Table of Contents

November 2025 Challenge: "Wait, This Was Printed? How Are There No Layer Lines?"

Challenge Overview

Can you achieve the smoothest, most layer-line-free surface finish possible? This challenge pushes your printer tuning, slicer settings, and material knowledge to the limit. The goal is simple but difficult: create a 25mm cube with 2 walls and no top that looks so smooth, people question whether it was actually 3D printed!

This challenge focuses on:

- Surface finish quality and smoothness

- Proper printer calibration and tuning

- Optimal slicer settings for layer adhesion

- Material selection and temperature control

- The art of making layer lines disappear

Challenge Rules

Materials & Constraints

- Filament: 3D Fuel filament (any type: PLA+, Pro PLA+, PCTG etc.)

- Nozzle Requirement: Must use a 0.4mm nozzle (REQUIRED)

- Estimated Filament Usage: Approximately 3 grams (for reference only)

- Model Specification:

- Dimensions: Exactly 25mm × 25mm × 25mm cube (REQUIRED)

- Wall Count: Exactly 2 walls (no more, no less) (REQUIRED)

- Top Layers: 0 (no top surface)

- Bottom Layers: Standard (as needed for proper adhesion)

- Infill: 0% (hollow interior)

- Print Mode: Standard FDM/FFF printing (no resin printing)

Competition Categories

- Smoothest Surface: Best overall surface finish with minimal visible layer lines straight off the printer

- No post-processing allowed - cubes must be judged as-printed

Judging Criteria

- Layer Line Visibility (100%): The appearance and visibility of layer lines - less visible is better

- All cubes must meet basic challenge requirements (25mm cube dimensions, exactly 2 walls, no post-processing)

- Winner is determined solely by smoothness of surface and minimal layer line appearance

- Tiebreaker: If two prints are too close to differentiate, the fastest print time wins

Submission Requirements

- Physical Model: Bring your printed 25mm cube to the December meetup for judging

- Dimension Verification: Must be exactly 25mm x 25mm x 25mm

- Wall Count Verification: Must show exactly 2 walls when inspected

- Print Time: Record and report your total print time (used as tiebreaker if needed)

- Documentation: Include photos showing:

- Close-up surface details

- Overall cube appearance

- Cross-section or wall thickness (optional)

- Settings Documentation: Share your winning settings:

- Layer height

- Print temperature

- Print speed

- Cooling settings

- Any special techniques used

- Process Notes: Brief description of your approach

Evaluation Process

- Dimension & Wall Check: Verification of 25mm cube dimensions and exactly 2 walls (must pass to be eligible)

- Visual Inspection: Expert panel examines layer line visibility under good lighting

- Community Voting: People's choice for most impressive result

Prizes & Recognition

Awards

- Smoothest Surface Winner: Best layer-line elimination straight off the printer

- People's Choice Award: Community favorite

Documentation

- Winner photos for social media sharing

- Settings profiles shared with community

- Technique documentation for learning

Timeline

- Challenge Announcement: November 12, 2025 (at November meetup)

- Submission Deadline: December 10, 2025 (at December meetup)

- Judging Period: December 10, 2025 (during December meetup)

- Winner Announcement: December 10, 2025 (end of December meetup)

Model Creation Instructions

Using the Provided Model

Download the pre-configured cube:

- File Location: Challenge Files/November2025/Cube.3mf

- Pre-configured: Already set to 25mm × 25mm × 25mm with 2 walls and no top

- Ready to slice: Import into your slicer and adjust settings for your printer

Creating the Cube Model from Scratch

Using Bambu Studio

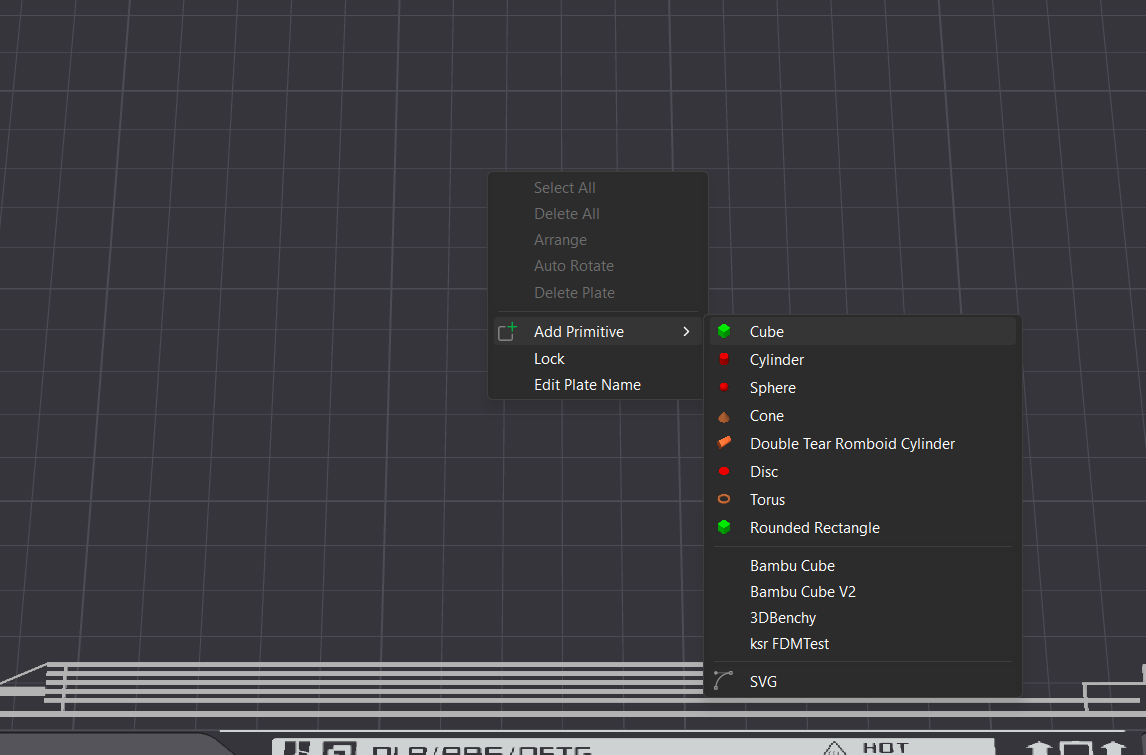

Step 1: Add Primitive

- Open Bambu Studio to a new project

- Right-click on the build plate

- Select "Add Primitive"

- Select "Cube"

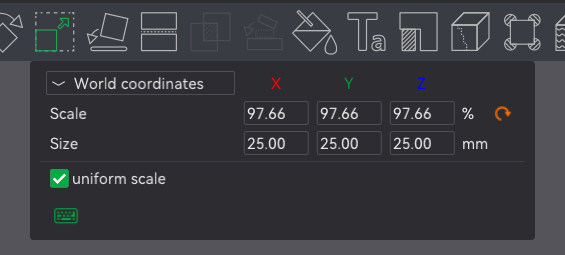

Step 2: Resize the Cube

- Click to resize the cube

- Set X to 25mm and Y and Z should also set to 25mm(If uniform scale cause issue you can uncheck)

Alternative Methods

- Fusion 360: Create square sketch (25mm × 25mm), extrude to 25mm height

- Tinkercad: Use cube shape, adjust dimensions to 25mm × 25mm × 25mm

- FreeCAD: Create cube with specified dimensions

- Any CAD Software: Simple cube 25mm × 25mm × 25mm

- Use provided file: Open

Challenge Files/November2025/Cube.3mfdirectly

Basic Cube Setup

Slicer Configuration

-

Create or Download Model:

- Use the provided

Challenge Files/November2025/Cube.3mffile - Or create using any CAD software (25mm × 25mm × 25mm cube)

- Or use the Bambu Studio/Orca Slicer primitive steps above

- Use the provided

-

Slicer Settings (Critical):

- Dimensions: 25mm × 25mm × 25mm

- Wall Count/Perimeters: 2

- Top Layers: 0

- Bottom Layers: 3-5 (as needed)

- Infill: 0%

- Layer Height: Your choice (hint: smaller = smoother, but slower)

-

Tips for Success:

- Lower layer heights (0.1mm-0.12mm) help reduce visible lines

- Slower speeds improve surface quality

- Temperature tuning is critical for layer adhesion

- Linear advance/pressure advance can help with consistency

- Proper cooling prevents warping without sacrificing layer bonding

- Material choice matters - some filaments naturally produce smoother surfaces

Advanced Techniques to Consider

-

Slicer Tricks:

- Adjust line width for better wall fusion

- Experiment with different seam positions

- Use variable layer heights if supported

- Try different acceleration/jerk settings

-

Material Selection:

- Experiment with different 3D Fuel filament types

- Colors can also give different appearance levels

What NOT to Do

- Do not exceed 2 walls

- Do not add a top surface

- Do not deviate from 25mm cube dimensions

- No post-processing allowed (no sanding, heat treatment, chemical smoothing, etc.)

Good luck creating the smoothest cube possible! May your layer lines vanish into nothingness!